AG-SAG Mill

FLSmidth’s AG (Autogenous) and SAG (Semi-Autogenous) mills are engineered for high-throughput, energy-efficient grinding in large-scale mineral processing operations. Built under the renowned Fuller-Traylor brand, these mills are designed to handle abrasive ores such as gold, copper, and iron with minimal ball charge for SAG and ore-only grinding for AG configurations. Their robust construction, advanced process control systems like ECS/ProcessExpert, and smart sensor technology such as LoadIQ enable optimized performance, reduced energy consumption, and extended uptime. With diameters ranging from 4.3 to 12.2 meters and power ratings up to 28,000 kW, FLSmidth’s AG-SAG mills deliver scalable, cost-effective solutions for demanding mining environments.

CITIC Heavy Industries is a global leader in the design and manufacture of SAG (Semi-Autogenous Grinding) mills, renowned for their scale, durability, and efficiency in mineral processing. With over 1,550 grinding mills delivered worldwide and a dominant 85% market share in China’s large-scale mining sector, CITIC’s SAG mills are engineered to handle high-capacity ore grinding with minimal energy consumption. These mills integrate advanced design features such as optimized liner profiles, precision steel ball loading, and high-efficiency rotational speeds to achieve crushing ratios up to 150:12. Built to international standards including ASTM and AGMA, CITIC’s SAG mills are trusted across more than 50 countries for their reliability in processing hard, abrasive ores in gold, copper, and iron mining operations.

Banana Screen

Metso:Outotec’s banana screens—also known as multi-slope screens—are engineered for high-capacity, high-efficiency screening in demanding mining and aggregate applications. Designed with variable elliptical motion and modular components, these screens deliver superior stratification and faster material travel, resulting in optimized throughput and reduced blinding. Available in multiple series including EF™, MF™, BSE™, and TS™, each model offers adjustable stroke and speed, robust wear protection, and easy maintenance access for maximum uptime and operator safety. With decades of experience and a global support network, Metso:Outotec banana screens are trusted for sustainable productivity and reliable performance in large-scale mineral processing operations.

Weir Minerals’ Enduron® ELITE banana screens—also known as multi-slope vibrating screens—are engineered for high-capacity, fine particle classification in demanding mining and mineral processing environments. Designed to deliver exceptionally high throughput per screening area, these screens feature a unique elliptical motion that enhances stratification and accelerates material travel, resulting in superior sizing efficiency and reduced energy consumption by up to 40%. With double-deck configurations, simplified maintenance, and integration-ready compatibility with Weir’s HPGR systems, Enduron® ELITE banana screens offer a robust, digitally empowered solution for sustainable, large-scale operations.

Conveyors

ContiTech, a division of Continental AG, is a global leader in conveyor belt technology, offering advanced solutions for material handling across mining, industrial, and infrastructure sectors. Their portfolio includes steel-cord and fabric-reinforced belts engineered for extreme loads, steep inclines, and harsh environments—delivering high tensile strength, minimal elongation, and exceptional resistance to wear, heat, and chemicals. With specialized products like STAHLCORD® steel cord belts, SICON® enclosed conveyors, and CONTIFLEX® EP belts, ContiTech ensures efficient, low-maintenance transport of bulk materials over long distances and complex terrains. Supported by comprehensive planning, monitoring, and after-sales services, ContiTech conveyors are trusted worldwide for reliability, innovation, and operational longevity.

Fenner Dunlop is a global leader in conveyor belting solutions, renowned for producing the toughest and longest-lasting belts in the industry. With over 150 years of engineering excellence, their products are designed to withstand the harshest conditions in mining, energy, and heavy industrial applications. Fenner Dunlop’s innovative carcass technologies—such as UsFlex® and Nova-X®—offer superior resistance to ripping, tearing, and impact, while their premium cover compounds ensure maximum durability and performance. Manufactured in North America, Europe, and Australia, their belts are backed by advanced monitoring tools like MyBelt and BIRDSi, enabling predictive maintenance and reduced downtime.

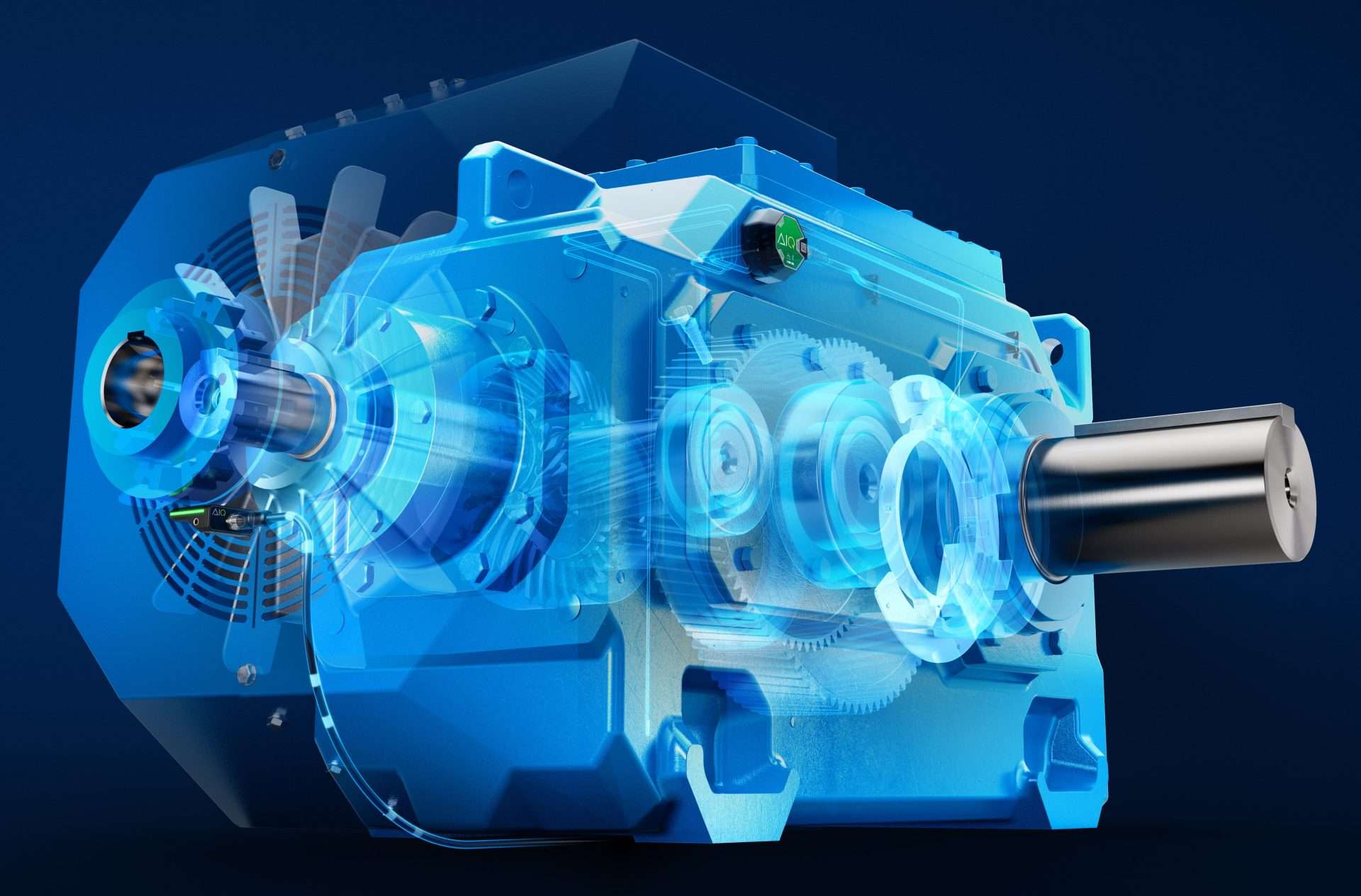

Gearmotors

Flender gearmotors are engineered to meet the rigorous demands of mining applications, delivering high torque, exceptional reliability, and compact design for efficient power transmission in harsh environments. Built on a modular system, Flender gear units—such as the PLANUREX and SIP series—offer scalable solutions for conveyor belts, crushers, mills, and hoists, with configurations tailored to confined spaces, extreme temperatures, and heavy loads2. Their advanced sealing systems, high power density, and integrated drive technologies ensure minimal downtime and optimal performance, even in dust-laden or mountainous terrains. Trusted globally, Flender gearmotors combine German precision with industry-specific innovation to keep mining operations running smoothly and sustainably.

Rossi gearmotors are engineered to meet the extreme demands of mining applications, delivering robust performance, high torque capacity, and long-term reliability in the harshest environments. With over 70 years of experience in industrial gear unit manufacturing and two decades of specialization in mining and cement sectors, Rossi offers a comprehensive range of bevel helical, planetary, and coaxial gearmotors capable of handling loads up to 3,000,000 Nm. Their solutions are tailored for conveyors, crushers, mills, and bulk handling systems, featuring advanced sealing systems, modular designs, and precision engineering that ensure optimal efficiency and minimal downtime. Trusted by over 150 mining plants worldwide, Rossi combines technical expertise with responsive project support to deliver turnkey drive systems that keep operations running smoothly and safely.

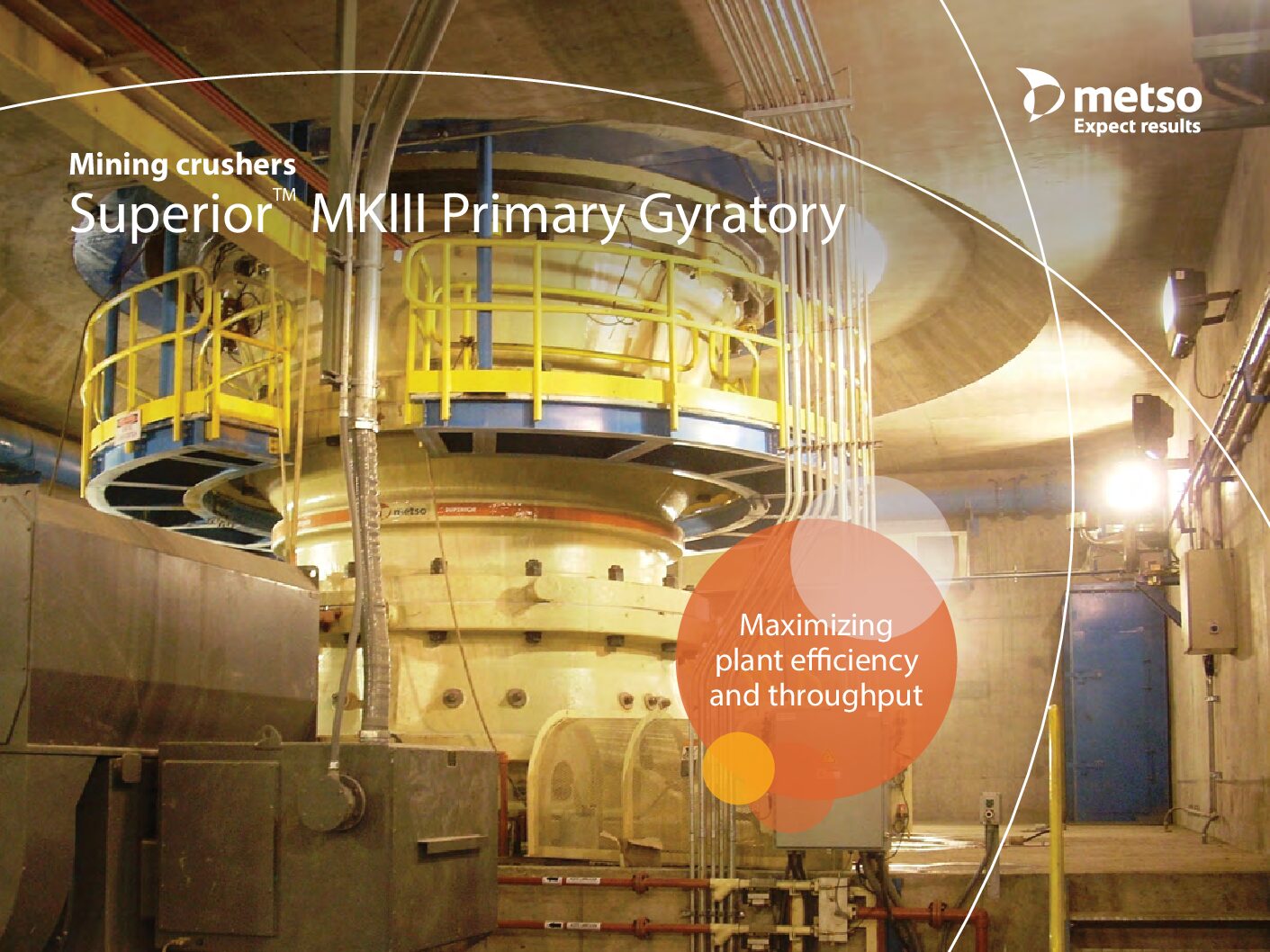

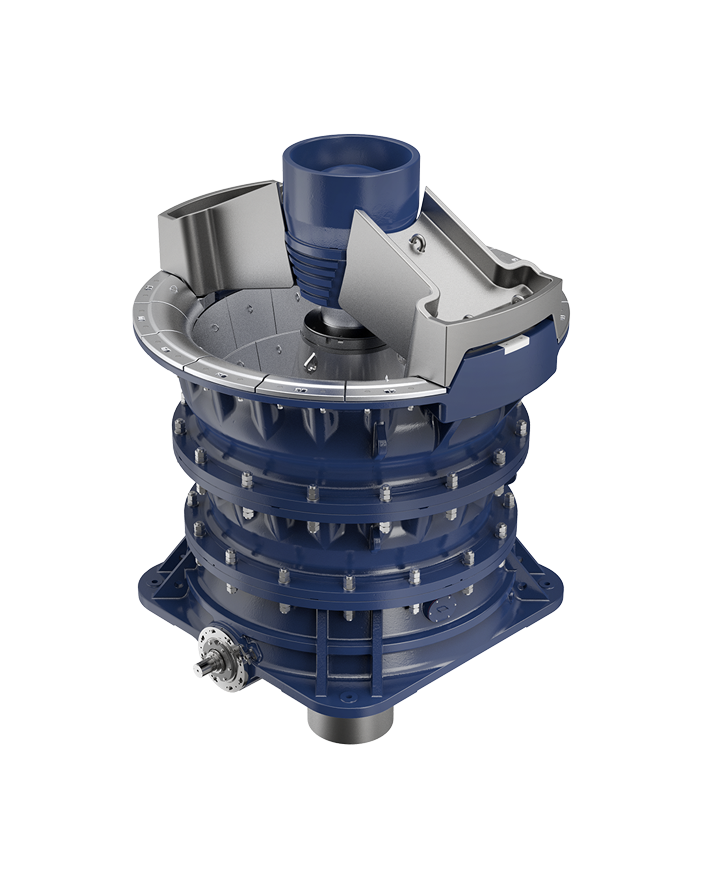

Gyratory Crushers

FLSmidth’s TSUV Gyratory Crushers represent the cutting edge of primary crushing technology, engineered for high-capacity, low-cost performance in the most demanding mining environments. With power handling capabilities up to 1500 kW and throughput rates reaching 15,000 tonnes per hour, these crushers deliver unmatched efficiency and scalability. The TSUV series features a Top Service design that allows safer, faster maintenance from above, reducing downtime and operational risk1. Integrated smart controls—such as automatic mantle adjustment and wear compensation—optimize crushing performance while extending equipment life. Built on over a century of engineering excellence, FLSmidth gyratory crushers are trusted worldwide for their durability, innovation, and ability to keep operations competitive even as ore grades decline.

Metso:Outotec’s Superior™ MKIII Series gyratory crushers represent the pinnacle of primary crushing technology, engineered for high-capacity, high-efficiency mineral processing operations. Designed to handle the toughest ores with minimal downtime, these crushers feature advanced mechanical improvements, increased installed power, and up to 30% higher throughput compared to previous models. With innovations like hydraulic shell separation, intelligent automation via the Mineral Crusher Pilot (MCP) system, and remote diagnostics, the MKIII crushers offer unmatched reliability, safety, and performance. Built for scalability and long-term durability, they are the preferred choice for large-scale mining operations seeking maximum productivity and cost-efficiency.