Steel rolling machines

Danieli is a global pioneer in hot steel rolling technology, offering advanced solutions that combine high productivity, energy efficiency, and flexible operation. Their hot rolling mills—ranging from wide plate mills to QSP-DUE thin-slab strip lines—are designed for coil-to-coil, semi-endless, and endless production modes, enabling seamless adaptation to diverse steel grades and product dimensions. With innovations like Power Mould casting, direct and endless rolling (DCR/ECR), and integrated reheating systems, Danieli’s mills significantly reduce CO₂ emissions and operational costs while maximizing output quality2. Trusted by leading steel producers worldwide, Danieli’s hot rolling machines embody the future of sustainable, high-speed steel manufacturing.

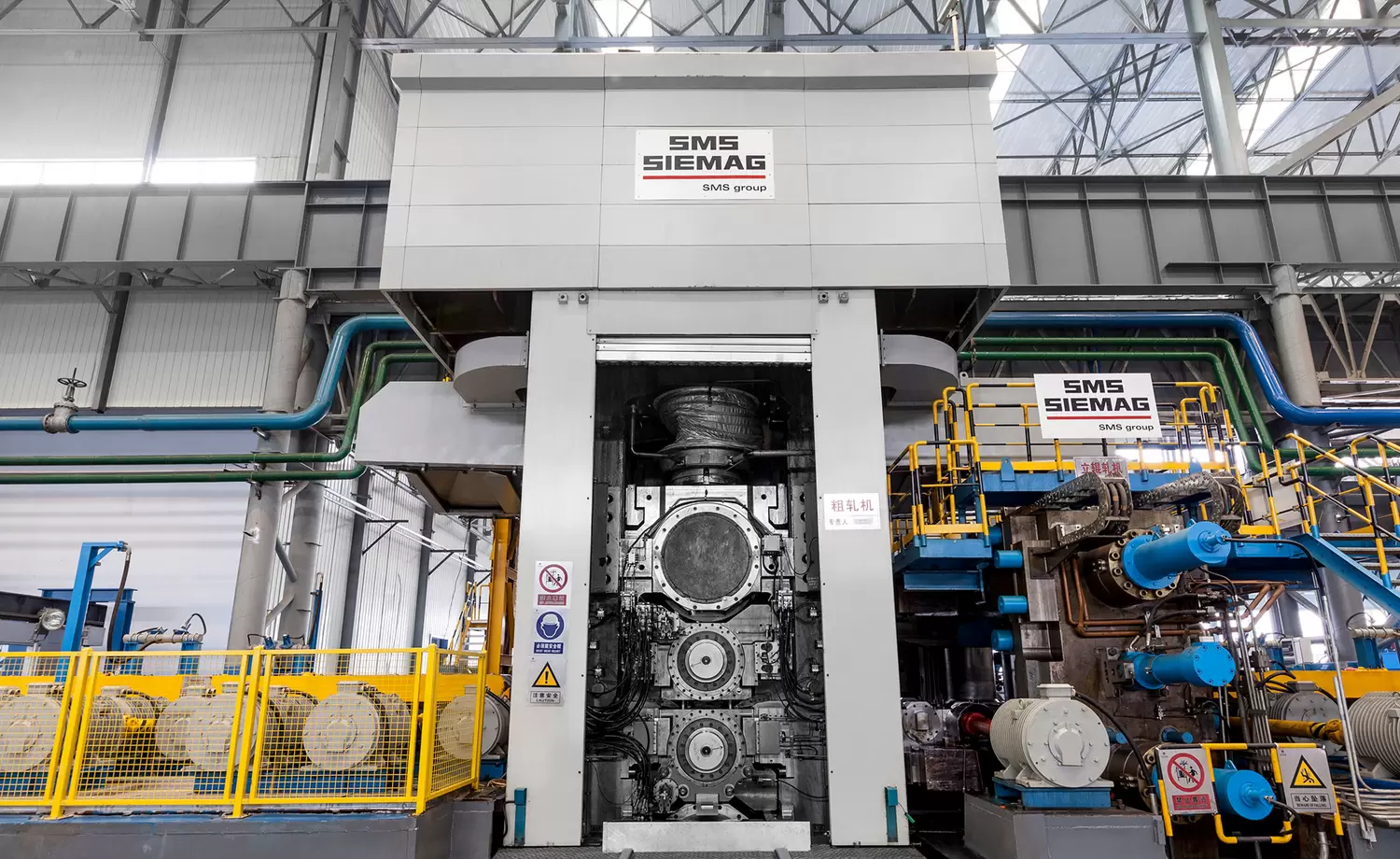

SMS Siemag, now part of SMS group, is a global leader in hot steel rolling technology, delivering high-performance solutions for flat and long product manufacturing. Their hot strip mills are engineered for maximum flexibility, precision, and throughput, capable of producing steel gauges from 1.2 mm to 25.4 mm with annual capacities exceeding 6 million tons. Equipped with advanced features like CVC® plus roll technology, hydraulic differential-tension loopers, and SIEFLEX®-HT spindles, these mills ensure superior control over profile, contour, and flatness2. SMS Siemag also integrates intelligent automation systems and modular process models—including PSC, PCFC, and CSC—to optimize rolling schedules, cooling strategies, and mechanical properties in real time. Trusted by major producers like Baosteel, their mills set global benchmarks for efficiency, sustainability, and premium steel quality.

Casting and forging parts

Bevel gears

Klingelnberg bevel gears, developed under the Oerlikon brand, are precision-engineered components widely used in steelmaking machinery for their exceptional durability, efficiency, and load-handling capabilities. Designed through Klingelnberg’s Closed Loop manufacturing process and optimized with advanced software like KIMoS, these gears undergo rigorous stages of cutting, hardening, grinding, and testing to ensure flawless performance in high-torque, high-temperature environments typical of rolling mills and heavy-duty drives. Their spiral and hypoid configurations offer superior meshing characteristics, reduced noise, and extended service life, making them a trusted choice for gearboxes and mechanical systems in steel production plants worldwide.

Casting and forging parts

Flanges

Melesi flanges, produced by Officine Ambrogio Melesi, are precision-forged components trusted in steelmaking machinery for their exceptional strength, dimensional accuracy, and compliance with international standards. With over a century of metallurgical expertise, Melesi manufactures a wide range of standard and custom flanges—including welding neck, blind, slip-on, and orifice types—engineered to withstand the extreme pressures and temperatures of steel production environments. Their flanges are crafted using advanced forging techniques and rigorous quality control, ensuring reliable performance in rolling mills, pressure vessels, and high-load mechanical systems. Recognized globally across sectors like power generation, petrochemicals, and heavy industry, Melesi flanges combine Italian craftsmanship with industrial resilience.